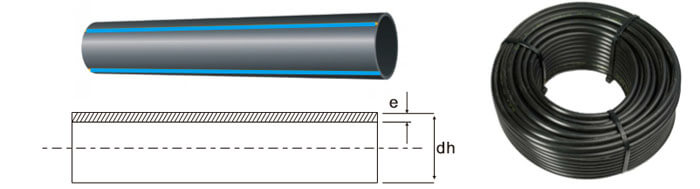

HDPE pipes are following ISO 4427 / AS / NZS 4130 / BS EN 12201 / SABS standards with black / blue colors, which get CE certificates and ISO 9001 quality management system certificates. Connected fittings are available.

1.Raw Materials: PE100, PE4710, PE100-RC

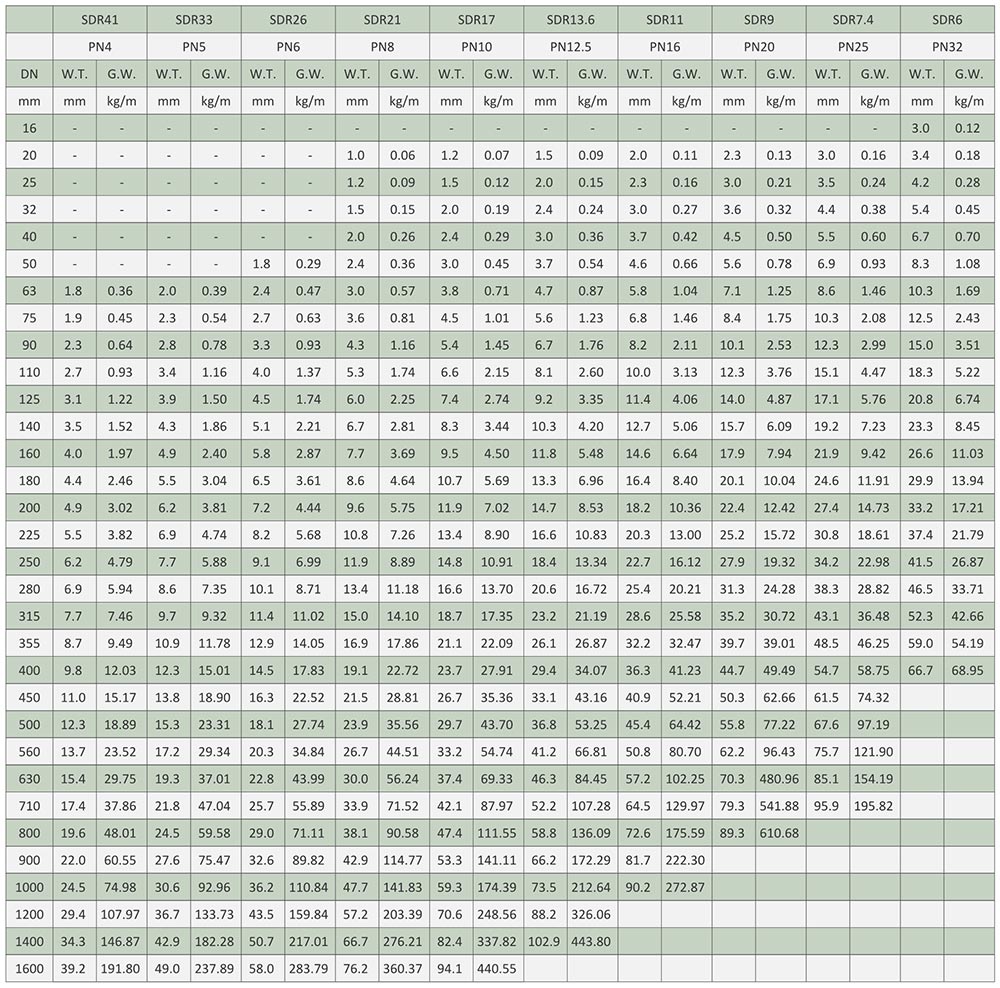

2. Size: DN20-1800mm (Can Be Customized)

3.Pressure Rating: SDR 41(PN4), SDR 33 (PN5), SDR 26 (PN6), SDR 21 (PN8), SDR 17 (PN10), SDR 13.6 (PN12.5), SDR 11 (PN16), SDR 9 (PN20), SDR 7.4 (PN25), SDR 6 (PN32)

4.Life: 70 Years

5.Certificate: WRAS/ UL /NSF /CE /SAA / FM

HDPE pipes and fittings are considered as the best choice for various projects, due to its high quality, reliability, as well as low mass for easy loading, transferring and installation. These products also have high bending capability and high resistance to impact and pressure in low temperature environment.

|

Product Name |

HDPE pipes |

|

Size |

DN20mm - 1800mm |

|

SDR |

SDR 41 (PN4), SDR 33 (PN5), SDR 26 (PN6), SDR 21 (PN8), SDR 17 (PN10), SDR 13.6 (PN12.5), SDR 11 (PN16), SDR 9 (PN20), SDR 7.4 (PN25), SDR 6 (PN32) |

|

Material |

High quality PE100 and PE4710 raw materials |

|

Colors |

Black, blue or as per request |

|

Standard |

ISO 4427/ ISO 9001/ AS/ NZS 4130/ BS EN 12201/ SABS standards |

|

Remarkss |

Customers' logo is available |

|

Sample |

Samples are available |

|

Packing |

International standard packing

Less than 110 mm by rolls, more than 110 mm by length 5.8 m or 11.8 m |

|

MOQ |

Negotiable |

|

Production |

Depending on the order quantity |

|

Certificates |

ISO 14001, ISO 9001, OHSAS 18001, CE BS EN 12201, WRAS certificates |

|

Warranty |

70 years for normal using |

|

Payment Term |

T/T or L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF |

We provide the HDPE pipes from dn20mm to 1800mm.

Note: Special specifications can be customized. Please contact us for more product information and pricing.

Please send your request to the email address: phds@phtopindustry.com (We will respond to you within 24 hours).

HDPE pipes and fittings includes:

1. HDPE Pipe, Pressure rating: SDR 41 - SDR 6, with size from DN16mm - 1600mm.

2. HDPE Butt Fusion fittings, Pressure rating: SDR 41 - SDR 6, with size from DN63mm - 1600mm.

3. HDPE Electrofusion fittings, Pressure rating: SDR 41 - SDR 6, with size from DN63mm - 400mm.

4. HDPE fabricated fittings, Pressure rating: SDR 41 - SDR 6, with size from DN20mm - 1600mm.

5. PP compressure fittings, Pressure rating: SDR 17 (PN10), SDR 11(PN16), with size from DN20mm - 400mm.

6. HDPE Special customized fittings, Pressure rating: SDR 41 - SDR 6, with size from DN110mm - 1600mm.

HDPE pipes and fittings are widely used in:

1. Urban water supply system, landscaping water supply network.

2. Oil and gas flow, gas drainage system.

3. Dredging pipeline engineering ( sand sediment transport ).

4. Underground firefighting system.

5. Cable covering ( HDPE conduit ).

6. Tunnel escape and ventilation engineering pipelines.

7. Industrial raw material conveying pipe network, industrial sewage discharge.

8. Fields of farmland irrigation and aquaculture projects.

Features of HDPE pipes and fittings: